Industrial Coffee Grinder for Bulk Brewing: A Essential Equipment

Wiki Article

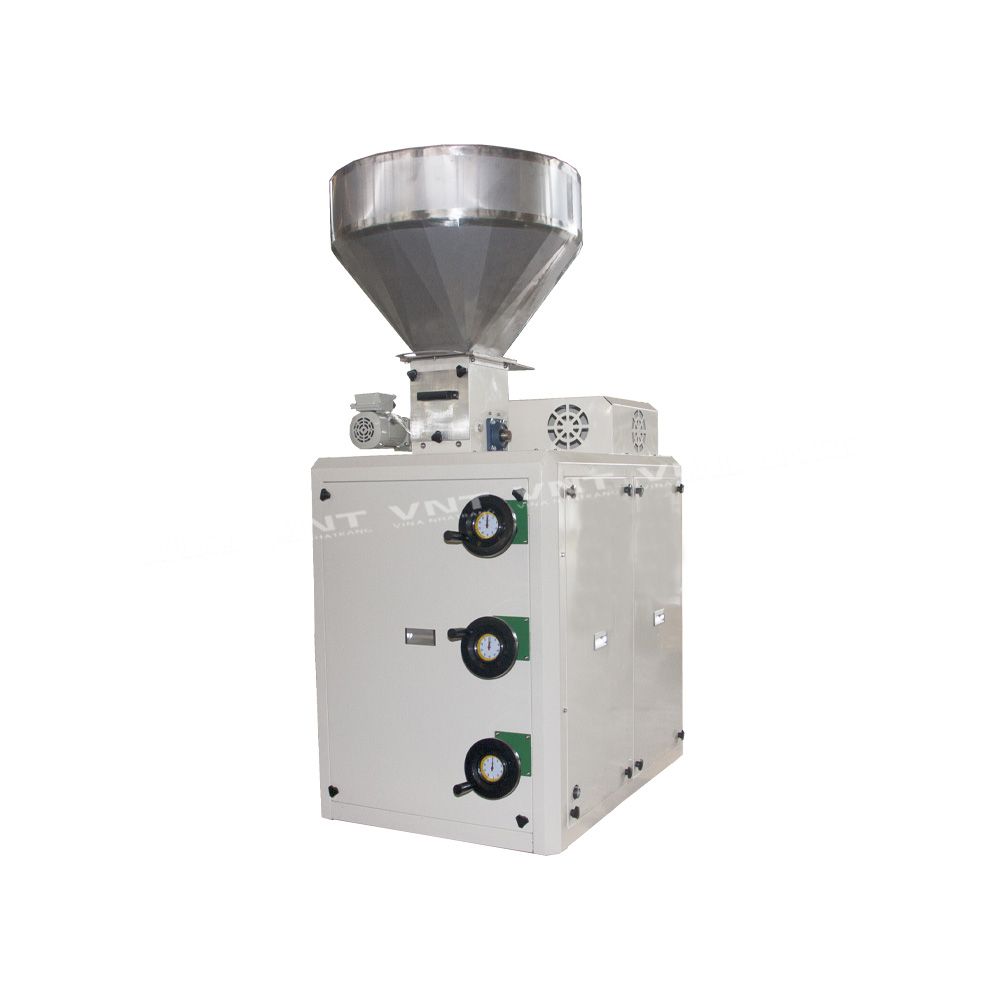

Industrial Coffee Mill Guide: Boost Performance and Top Quality

In the competitive landscape of coffee manufacturing, selecting the ideal industrial coffee mill plays an essential function in enhancing both performance and item top quality. Understanding the nuances of numerous grinder types and essential attributes-- such as customizable work settings and robust construction-- can dramatically influence the last flavor profile of the coffee. In addition, the optimization of the grinding process, combined with persistent upkeep, is important for maintaining efficiency gradually. As we check out these important components, it comes to be apparent that the effects expand beyond mere tools choice, impacting overall service success in manner ins which require closer assessment.Understanding Grinder Kinds

When selecting an industrial coffee grinder, understanding the numerous kinds readily available is essential for optimizing both taste removal and operational effectiveness. The two main kinds of grinders are blade mills and burr grinders. Blade grinders make use of sharp blades that slice coffee beans right into irregular sizes, resulting in uneven removal and possibly unwanted flavors. While blade mills are usually a lot more budget-friendly and appropriate for small procedures, they are normally not suggested for commercial usage.

Eventually, selecting the ideal sort of grinder is indispensable to maintaining top quality and efficiency in coffee production, making it vital for businesses to invest in high-grade burr grinders for optimal outcomes.

Key Functions to Take Into Consideration

Selecting a commercial coffee mill calls for careful consideration of numerous vital functions that can dramatically influence both performance and the general coffee experience. Among the main facets to evaluate is the grinding mechanism. Burr grinders are normally chosen over blade mills, as they give a consistent grind size, which is crucial for ideal removal and taste.An additional essential attribute is the mill's capability. A versatile grinder with numerous setups enables you to tailor the grind size to various developing techniques, enhancing the coffee's flavor profile.

The construction material additionally plays a function in durability and upkeep. Stainless-steel elements commonly offer durability and are easier to clean, which is crucial for keeping hygiene requirements. Evaluate the mill's noise degree, particularly in a busy coffee shop or manufacturing environment, where too much noise can be turbulent. Buying a grinder that stabilizes these features can greatly enhance both functional effectiveness and the quality of the coffee offered.

Optimizing Grinding Refine

To accomplish the most effective cause coffee preparation, enhancing the grinding procedure is crucial. The grind dimension considerably affects extraction, taste, and overall top quality of the brewed coffee. Different developing methods require details grind sizes; for circumstances, coffee requires a fine grind, while French press requires a crude texture. Comprehending the connection in between grind size click reference and brewing technique is the initial step in optimization.

In addition, monitoring the grinding speed can enhance the process. Slower grinding typically creates much less warm, maintaining fragile tastes and fragrances. Alternatively, much faster grinding may produce extreme warm, negatively affecting the coffee's high quality.

Upkeep and Treatment Tips

Correct upkeep and treatment of industrial coffee grinders are crucial for making certain optimum efficiency and durability. Routine cleansing is the structure of upkeep; residue buildup can affect taste and grinding efficiency. It is a good idea to clean up the grinder after each usage, cleaning down the exterior and removing any coffee premises from the burrs.Furthermore, evaluate the grinding burrs for wear and tear. Plain burrs can compromise work consistency, so they ought to be replaced as necessary. Industrial Coffee Grinder. Occasionally adjusting the grinder is additionally critical, as this preserves the desired work size for various developing techniques

Lubrication of relocating components must be carried out according to the supplier's specs, as this decreases rubbing and extends the life of the equipment. It is vital to utilize food-grade lubricants to make certain safety and compliance with health and wellness policies.

Last but not least, keep the mill in a steady and completely dry setting to stop rust and corrosion. By sticking to these upkeep and care pointers, operators can improve the efficiency of their industrial coffee mills while guaranteeing high-quality outcome and prolonged operational life.

Roi Analysis

Examining the roi (ROI) for industrial coffee mills is crucial for companies seeking to enhance their coffee manufacturing capacities. An extensive ROI evaluation aids establish the financial viability of purchasing top notch mills, permitting organizations to weigh the first prices versus Get More Information prospective gains.Evaluate the purchase rate of the grinder, consisting of installment and any type of necessary alterations to existing facilities. High-performance grinders frequently lead to minimized grinding time and increased throughput, which can dramatically improve productivity.

Additionally, take into consideration the influence on product top quality. Industrial Coffee Grinder. Superior grinders yield a more consistent work size, which can boost flavor accounts and client fulfillment, ultimately driving sales. By boosting the quality of the end product, organizations can validate greater pricing, causing increased profits

Conclusion

In recap, an industrial coffee grinder plays a crucial role in improving both performance and product top quality within coffee production. By choosing top quality burr mills outfitted with necessary features such as adjustable work setups and durable building and construction, businesses can make sure optimum taste extraction. Moreover, normal upkeep is essential for maintaining mill efficiency and making best use of customer complete satisfaction. Ultimately, the tactical investment in a dependable mill adds dramatically to improved revenue and competitiveness in the coffee market.In the competitive landscape of coffee production, selecting the right commercial coffee mill plays an essential duty in boosting both effectiveness and product quality. The 2 main types of grinders are blade mills and burr mills. Within the burr grinder category, there are level burr grinders and conical burr mills, each with its benefits. Burr grinders are generally favored over blade grinders, as they offer a consistent work size, which is essential for optimal extraction and flavor.

In recap, a commercial coffee read this grinder plays a crucial function in boosting both performance and item high quality within coffee production.

Report this wiki page