Find the Top Offers on Industrial Coffee Grinder Brands Right Now

Wiki Article

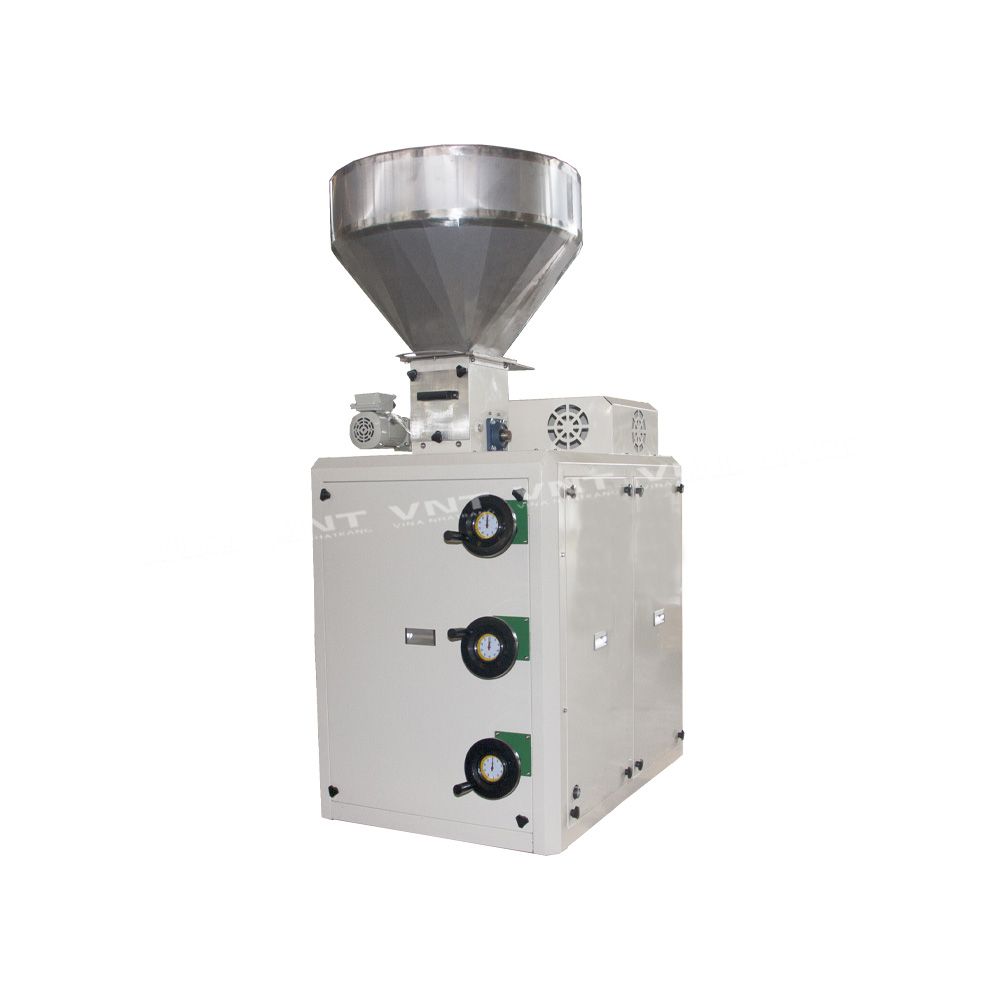

Industrial Coffee Grinder Guide: Boost Efficiency and High Quality

In the affordable landscape of coffee manufacturing, picking the right industrial coffee grinder plays a crucial role in improving both effectiveness and product top quality. Understanding the nuances of numerous grinder types and key functions-- such as adjustable work setups and durable building and construction-- can dramatically affect the final flavor profile of the coffee. The optimization of the grinding procedure, coupled with persistent upkeep, is important for maintaining efficiency over time. As we explore these vital aspects, it becomes noticeable that the implications extend past simple equipment option, influencing general business success in manner ins which require closer assessment.Comprehending Mill Types

When choosing an industrial coffee grinder, comprehending the various types available is important for maximizing both taste extraction and functional performance. The two main kinds of mills are blade grinders and burr mills.

Ultimately, picking the right kind of grinder is essential to keeping quality and performance in coffee manufacturing, making it crucial for companies to purchase premium burr grinders for optimal outcomes.

Key Features to Take Into Consideration

Selecting a commercial coffee mill requires careful consideration of several essential attributes that can substantially affect both efficiency and the general coffee experience. One of the key facets to review is the grinding device. Burr mills are usually preferred over blade mills, as they provide a constant work size, which is essential for optimal extraction and flavor.One more vital attribute is the mill's capacity. A versatile grinder with several setups allows you to tailor the grind dimension to different developing approaches, enhancing the coffee's flavor account.

The building product additionally contributes in longevity and maintenance. Stainless steel elements frequently offer durability and are easier to clean up, which is important for keeping hygiene standards. Last but not least, assess the grinder's noise degree, specifically in a hectic café or manufacturing environment, where excessive noise can be turbulent. Investing in a mill that balances these functions can substantially improve both operational performance and the top quality of the coffee offered.

Optimizing Grinding Process

To attain the ideal results in coffee prep work, optimizing the grinding procedure is important. The grind dimension considerably affects extraction, flavor, and overall quality of the made coffee.

Additionally, checking the grinding speed can enhance the process. Slower grinding often creates much less heat, protecting fragile flavors and scents. On the other hand, quicker grinding might produce excessive warm, negatively affecting the coffee's top quality.

Maintenance and Treatment Tips

Proper maintenance check this and care of industrial coffee mills are important for ensuring ideal efficiency and longevity. Normal cleansing is the structure of upkeep; residue accumulation can influence flavor and grinding effectiveness. It is a good idea to cleanse the mill after each use, cleaning down the exterior and eliminating any type of coffee grounds from the burrs.Additionally, check the grinding burrs for wear and tear. Dull burrs can jeopardize grind uniformity, so they should be replaced as needed. Industrial Coffee Grinder. Regularly calibrating the mill is likewise essential, as this keeps the desired work size for numerous brewing approaches

Lubrication of moving parts must be executed according to the producer's requirements, as this minimizes rubbing and prolongs the life of the devices. It is vital to use food-grade lubes to ensure security and compliance with health regulations.

Last but not least, maintain the grinder in a completely dry and secure setting to avoid rust and corrosion. By sticking to these maintenance and care pointers, drivers can address improve the performance of their commercial coffee grinders while making sure top quality output and expanded functional life.

Roi Evaluation

Evaluating the roi (ROI) for industrial coffee grinders is crucial for organizations seeking to optimize their coffee manufacturing abilities. An extensive ROI analysis helps establish the monetary practicality of investing in high-grade mills, allowing organizations to consider the first prices against potential gains.To conduct an extensive ROI evaluation, companies should consider numerous essential elements. Evaluate the purchase price of the grinder, consisting of installment and any type of needed adjustments to existing framework. Next, compute operational costs, consisting of energy consumption, maintenance expenditures, and labor effectiveness renovations. High-performance mills often bring about reduced grinding time and increased throughput, which can dramatically enhance productivity.

Furthermore, think about the effect on item top quality. Industrial Coffee Grinder. Superior grinders produce an even more consistent grind dimension, which can enhance flavor profiles and client complete satisfaction, eventually driving sales. By enhancing the quality of the final product, services can validate higher prices, resulting in raised profits

Verdict

In recap, an industrial coffee grinder plays a critical duty in enhancing both effectiveness and product high quality anonymous within coffee manufacturing. Inevitably, the calculated investment in a reliable mill contributes dramatically to improved earnings and competition in the coffee sector.In the affordable landscape of coffee manufacturing, picking the appropriate commercial coffee grinder plays a pivotal duty in boosting both efficiency and item top quality. The two key kinds of mills are blade mills and burr grinders. Within the burr mill classification, there are level burr grinders and conelike burr mills, each with its advantages. Burr grinders are usually chosen over blade grinders, as they provide a regular grind size, which is crucial for optimal extraction and taste.

In recap, a commercial coffee grinder plays a critical duty in improving both performance and item high quality within coffee production.

Report this wiki page